A lathe chuck is typically used to hold a rotating work piece (such as a bar or blank). Some chucks can also hold irregularly shaped objects (ones that lack radial symmetry) and in some applications, the tool or work piece being held by the chuck remains stationary while another tool or work piece rotates.

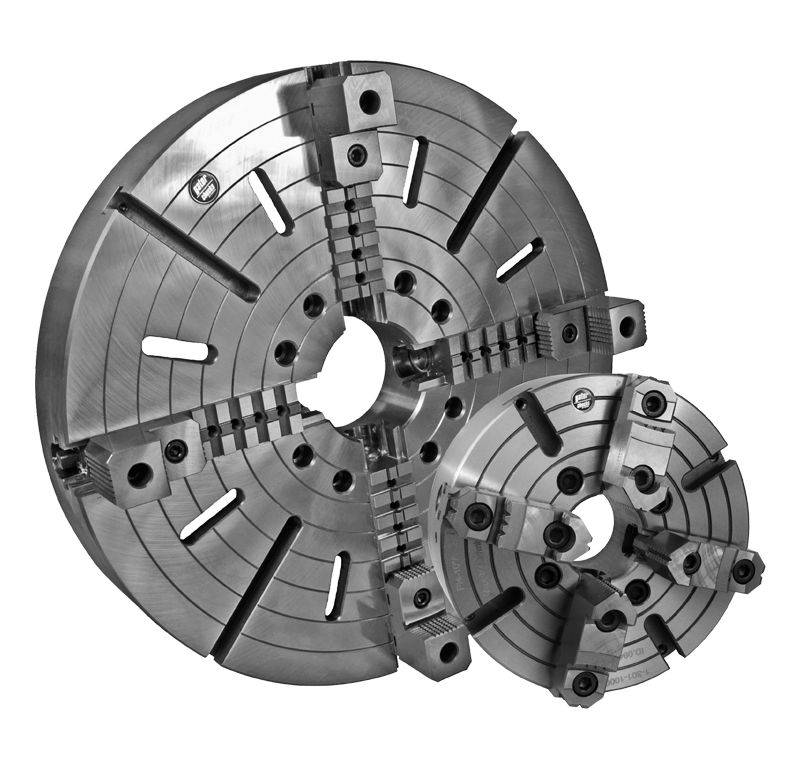

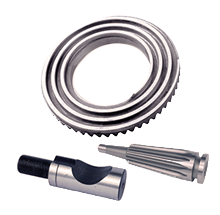

A self-centering chuck, also known as a scroll chuck, self centers around the work piece. The term universal (Gator PS series) or precision (Gator PO series) also refers to this type of chuck. These chucks are best suited to grip circular or hexagonal cross-sections when very fast, reasonably accurate T.I.R. (total indicator run out) is desired. Sometimes this type of chuck has 4 or 6 jaws instead of 3. More jaws grip the work piece more securely if it is truly cylindrical, and thin-walled work will deform less. Four jaws are also useful for square bar work.

There are also self-centering chucks that are adjustable (Gator PA and EA series) that can be used to further improve the concentricity after the work piece has been gripped. These are commonly referred to as adjustable chucks.

Three-jaw chucks are often used on lathes, grinders, rotary tables and indexing heads and typically are produced with Cast Iron, Cast Steel or Forged Steel materials. With an independent (Gator PI and PEI series chuck, each jaw can be moved independently. They most often have four jaws. The independence of the jaws makes these chucks ideal for gripping non-circular cross sections and gripping circular cross sections with extreme precision (when the last few hundredths of a millimeter, or thousandths of an inch of run out must be manually eliminated). The non-self-centering action of the independent jaws makes centering highly controllable (for an experienced user), but at the expense of speed and ease. Four-jaw chucks are almost never used for tool holding.

Four-jaw independent chucks can be found on lathes, grinders, rotary tables and indexing heads and typically are produced with Cast Iron, Cast Steel or Forged Steel materials.